|

Our soaps are handcrafted, benefiting from all the benefits of the ancestral know-how in cold saponification by our Master soap maker.

Cold saponification is a traditional artisanal method, which preserves all the benefits of the plants.

This process is based on a reaction that occurs by mixing fats (oils or vegetable butters) with a strong base (soda).

|

All the benefits of the products preserved:

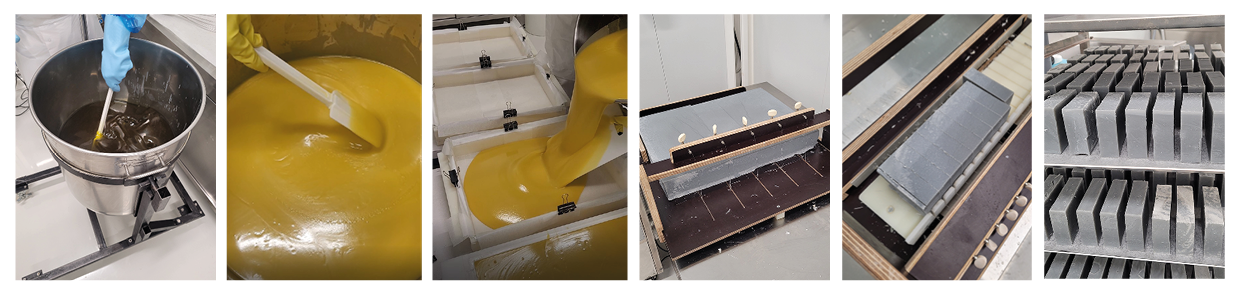

| We have chosen to produce according to the ancestral method of cold saponification , in which no oil is heated and only the butters are melted at low temperature to become liquid. Thus, all the benefits and moisturizing properties of the vegetable oils and butters are preserved for a nourished and moisturized skin. A technique that works by excess oil, meaning that more vegetable oil is used than necessary to transform the soda into soap. This makes it possible to obtain soaps known as "surgras" at 6%, naturally rich in glycerin for a repairing effect all in softness, nourishing, hydrating and soothing. It is a long method for us, Artisan soap makers, because the time of drying, called "Cure", of our soaps takes 5 weeks, in order to obtain a soft care in the respect of the vegetable matters. |

This cold saponification process is carried out in our laboratory, in the heart of the Drôme:

|

DISCOVER THE SAPONIFICATION PROCESS IN OUR WORKSHOP

What is the difference with the other methods, the hot saponification and the bubble method?

| HOT SAPONIFICATION | BUBBLE METHOD |

The oils are heated at a very high temperature around 120° C for about 10 days, which allows an acceleration of the process, but process, but at what cost? - Oils and butters lose their natural properties by being heated at high temperature. - These soaps are harder and sometimes drying since there is no and more glycerin (removed and resold). - The ecological impact is less good, even if they are real biodegradable soaps, because the cooking is energy consuming and the method requires several washes to remove the soda which is not entirely transformed into soap. | The soap maker heats these pellets in a machine called an extruder and adds perfumes, colorants and sometimes non-vegetable or natural additives, without essential interest for the skin. The whole is mixed and it comes out small soaps of all colors that can be stamped and used in the moment. These soaps are often wrongly sold on the markets as handmade soaps, which is not the reality of their manufacturing. |

Cold saponification is the only ancestral method, natural, respectful of nature and healthy for the skin.

|